JS Polymerized Waterproof Emulsion

Product Parameter

| Ingredients | Environmentally friendly waterproof emulsion and additives |

| Viscosity | 500-850mPa.s |

| pH value | 5-7 |

| Solid content | 50±1% |

| Country of origin | Made in China |

| Model NO. | BPR-7055 |

| Physical state | White viscous liquid |

| Proportion | 1.02 |

Product Application

1. Widely used in waterproof, anti-leakage, moisture-proof and other projects of exterior walls, toilet kitchens, pools, basements, roofs and other buildings.

2. Used for anti-leakage and moisture-proof masonry made of porous materials such as aerated concrete and hollow bricks.

Product Features

● Strong adhesion

● Good flexibility

● Excellent waterproof performance

● Convenient construction

Product Instructions

Paint construction

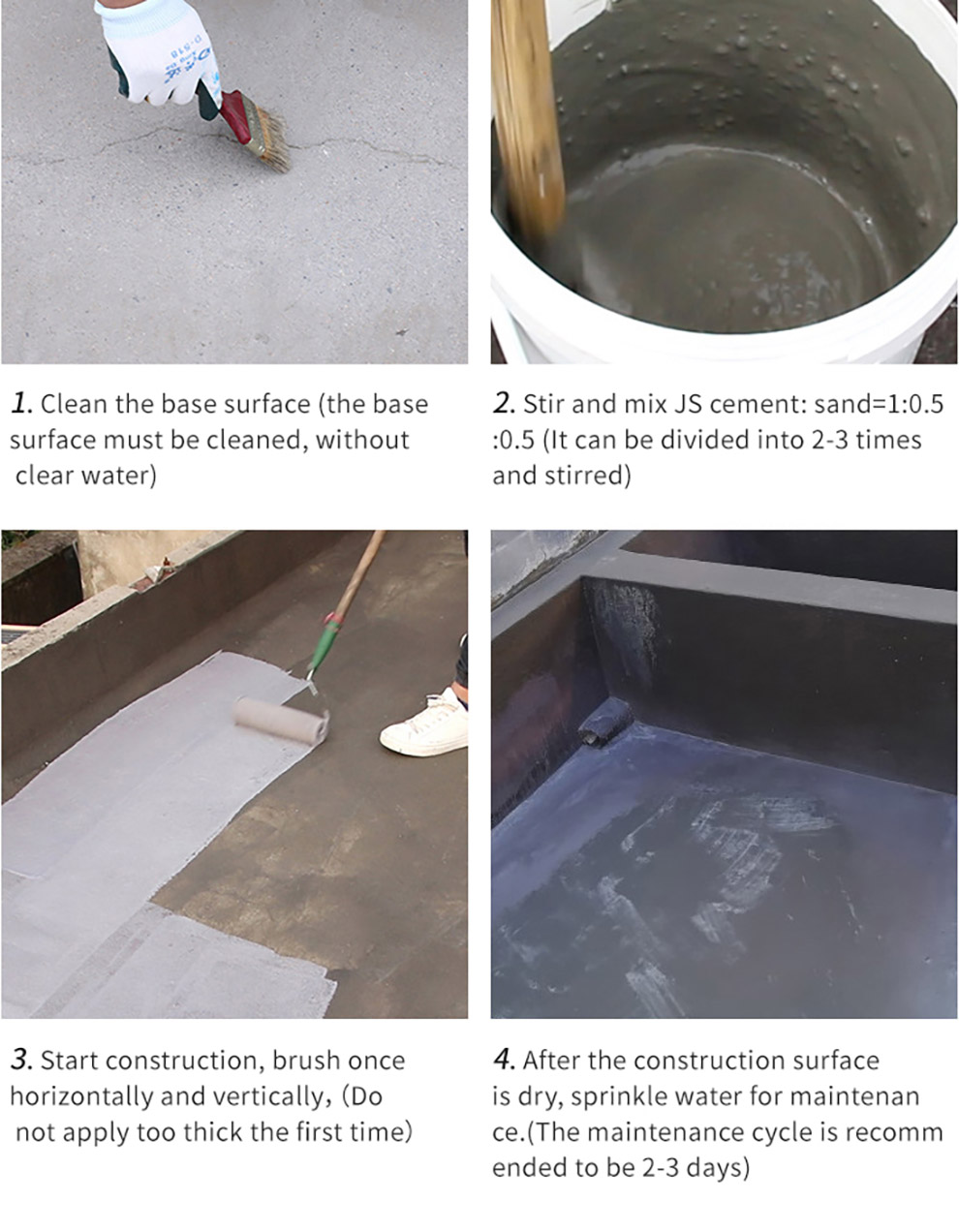

1. Ingredients, mix evenly according to the weight ratio of waterproof emulsion glue: cement = 1: (0.9-1.0).

2. According to the thickness required by the factory design, it can be painted 2-3 times.

3. It can be applied by brushing, rolling or scraping during construction. Each time you apply it, wait until the surface of the layer is dry (about 1-2 hours), and then apply again.

Tool cleaning

Please use clean water to wash all utensils on time after stopping in the middle of painting and after painting.

Dosage

1-2kg/㎡

Packaging specification

25KG

Storage method

Store in a cool and dry warehouse at 0°C-35°C, avoid rain and sun exposure, and strictly prevent frost. Avoid stacking too high.

Substrate treatment

The collective surface should be smooth and solid, free of honeycomb, pockmarked surface, dust and oil, and the angles of yin and yang should be made into radians; defective parts of the base should be repaired before construction.

Moldy surface

1. Shovel with a spatula and sand with sandpaper to remove mildew.

2. Brush 1 time with appropriate mold wash water, and rinse with clean water on time, and let dry completely.

Points to Attention

Construction and use suggestions

1. Carefully read the instructions for using this product before construction.

2. It is recommended to try it in a small area first, and if you have any questions, please consult on time before using it.

3. Avoid storage at low temperatures or exposure to sunlight.

4. Use according to product technical instructions.

Executive standard

GB/T23445-2009 (Ⅱ) standard

Product construction steps

Product Display