Efficient Pure Black Interior Wall Paint

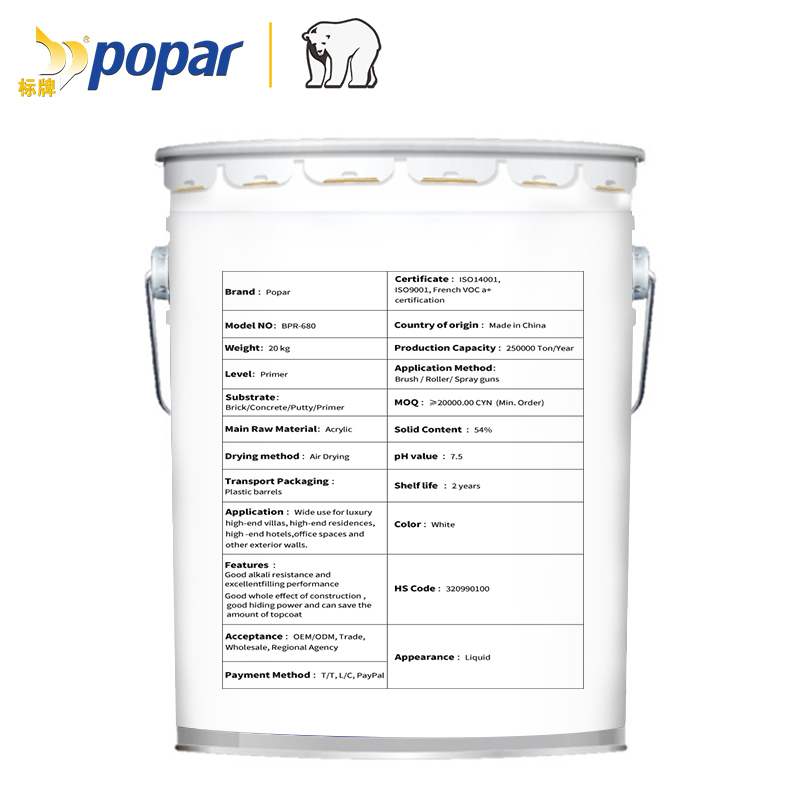

Technical data

| Ingredients | Water ,water-based deodorizing emulsion, environmental pigment,environmental additive |

| Viscosity | 108Pa.s |

| pH value | 7.5 |

| Water resistance | 600 times |

| Theoretical coverage | 0.95 |

| Drying time | Surface dry in 2 hours, hard dry in about 24 hours. |

| Solid content | 45% |

| Proportion | 1.3 |

| Country of origin | Made in China |

| Model NO. | BPR-810B |

| Physical state | white viscous liquid |

Product Application

It is widely used in hotels, coffee bars, Internet cafes, and restaurants for indoor wall coating.

Product Features

• High hiding power

• Good gloss

Product Construction

Application instructions

The surface must be clean, dry, neutral, flat, free of floating dust, oil stains and sundries, the leaking part must be sealed, and the surface must be polished and smoothed before painting to ensure that the surface humidity of the pre-coated substrate is less than 10%, and the pH value is less than 10.

The quality of the paint effect depends on the flatness of the base layer.

Application conditions

Please do not apply in wet or cold weather (the temperature is below 5°C and the relative degree is above 85%) or the expected coating effect will not be achieved.

Please use it in a well ventilated place. If you really need to work in a closed environment, you must install ventilation and use appropriate protective devices.

Tool Cleaning

Please use clean water to wash all utensils on time after stopping in the middle of painting and after painting.

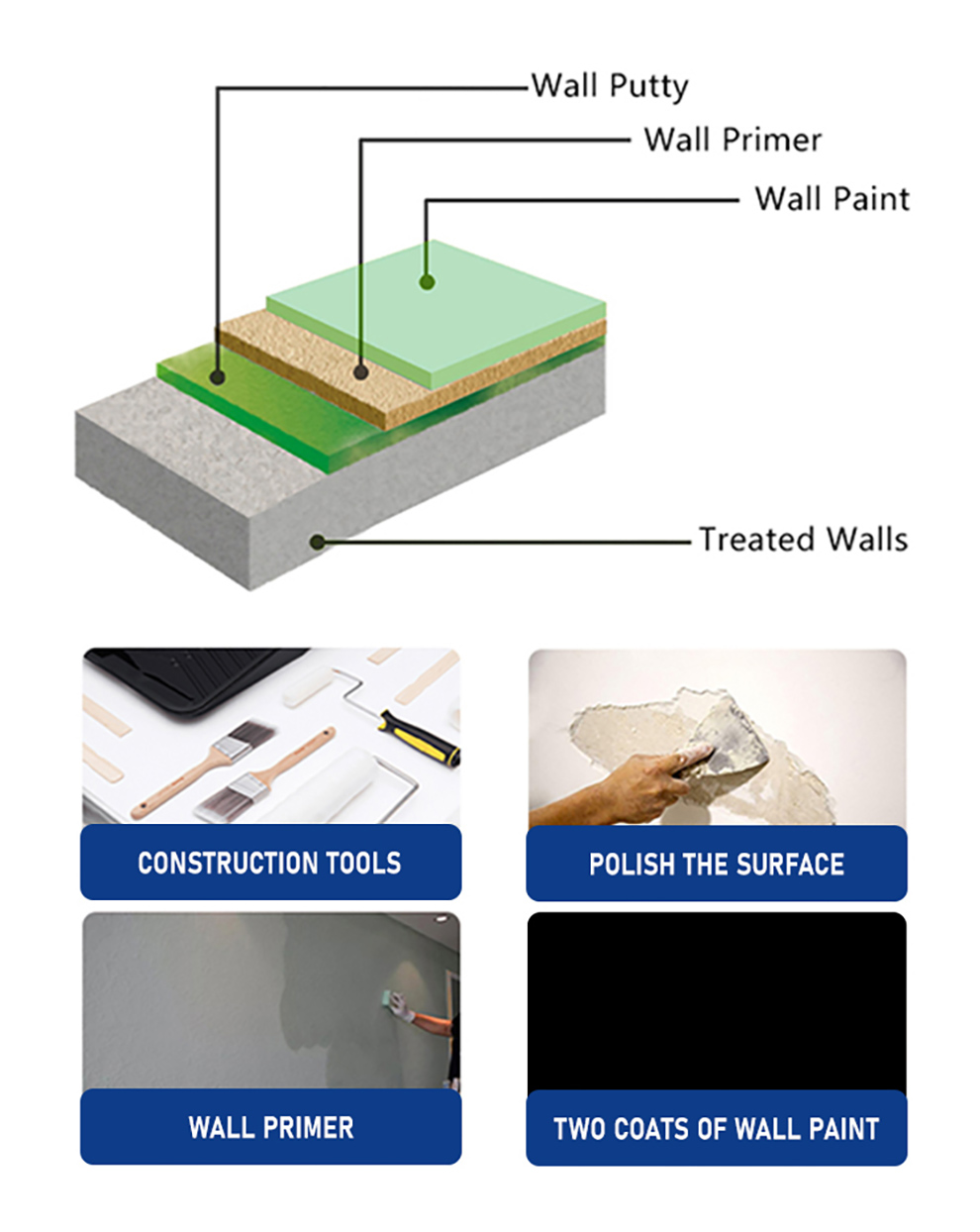

Coating system and coating times

Base surface treatment: remove dust, oil stains, cracks, etc. on the base surface, spray glue or interface agent to increase adhesion and alkali resistance.

Putty scraping: Fill the uneven part of the wall with low alkaline putty, scrape twice horizontally and vertically alternately, and smooth it with sandpaper after scraping each time.

Primer: Brush a layer with a special primer to increase coating strength and adhesion of the paint.

Brush topcoat: according to the type and requirements of the paint, brush two to three topcoats, wait for drying between each layer, and refill putty and smooth.

Theoretical paint consumption

9.0-10 square meters/kg/single pass (dry film 30 microns), due to the roughness of the actual construction surface and the dilution ratio, the amount of paint consumption is also different.

Packaging specification

20KG

Storage method

Store in a cool and dry warehouse at 0°C-35°C, avoid rain and sun exposure, and strictly prevent frost. Avoid stacking too high.

Instructions

Application instructions: The surface must be clean, dry, neutral, flat, and free of floating ash, oil stains and foreign matters. Water-leaking positions must undergo waterproof treatment. Before coating, the surface should be polished and leveled to ensure that the surface humidity of the pre-coated substrate is <10% and the pH value is

Application conditions: Wall temperature ≥ 5 ℃, humidity ≤ 85%, and good ventilation.

Application methods: Brush coating, roller coating and spraying.

Dilution ratio: Dilute with a proper amount of clear water (to the extent of being suitable for pasting) Water to paint ratio 0.2:1 . Remember mixing well before using

Theoretical paint consumption: 4-5㎡/Kg (two times of roller coating); 2-3㎡/Kg (two times of spraying). (The actual amount varies slightly due to the roughness and looseness of the base layer),

Recoating time: 30-60 minutes after surface drying, 2 hours after hard drying, and recoating interval is 2-3 hours (which may be duly extended under low-temperature and high-humidity conditions).

Maintenance time: 7 days/25℃, which may be duly extended under low-temperature and high-humidity conditions to obtain a solid film effect. In the process of paint film maintenance and daily use, it is suggested that doors and windows should be closed for dehumidification in high humidity weather (such as Wet Spring and Plum Rain).

Tool Cleaning : After or between applications, please clean the tools with clean water in time in order to prolong tool life. The packaging bucket can be recycled after cleaning, and packaging waste may be recycled for reuse.

Points to Attention

Construction and use suggestions

1. Carefully read the instructions for using this product before construction.

2. It is recommended to try it in a small area first, and if you have any questions, please consult on time before using it.

3. Avoid storage at low temperatures or exposure to sunlight.

4. Use according to product technical instructions.

Executive standard

This product fully complies with National/Industry Standards:

GB18582-2008 "Limits of Hazardous Substances in Adhesives for Interior Decoration Materials"

GB/T 9756-2018 "Synthetic Resin Emulsion Interior Wall Coatings"

Product construction steps

Product Display