Liquid Granite Paint Exterior Wall Paint Texture

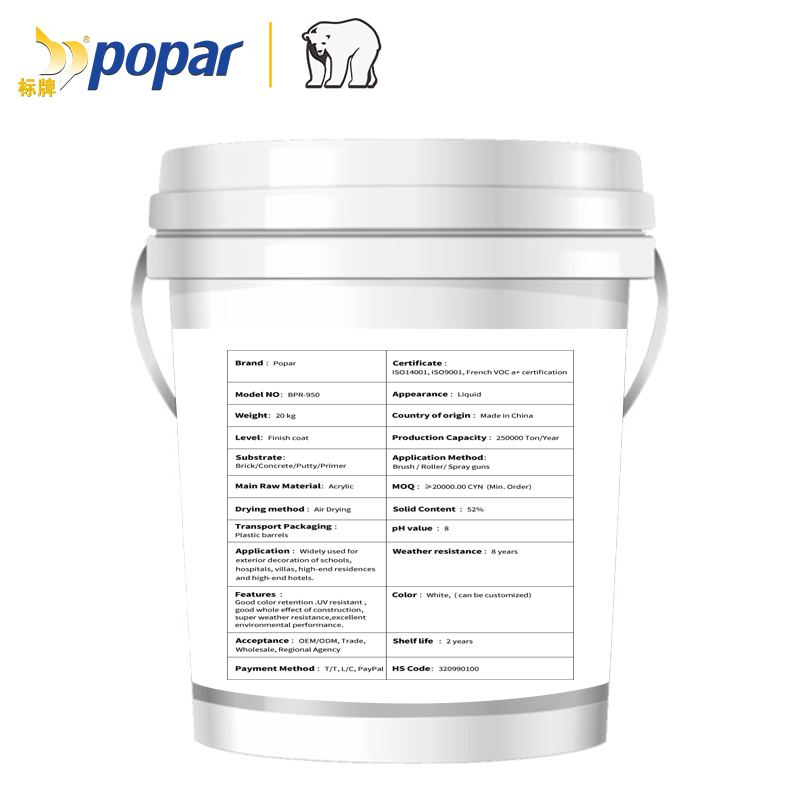

Product Parameter

| Ingredients | Water; Environmental protection emulsion based on water; Natural sand mining; Environmental protection additives |

| Viscosity | 80Pa.s |

| pH value | 8 |

| weather resistance | more than 20 years |

| Country of origin | Made in China |

| Model NO. | BPF-S942 |

| Physical state | Viscous gravel liquid |

Product Features

1. The effect of imitation granite is realistic, showing the natural grain of granite, and the load of the wall is light.

2. High stain resistance, self-cleaning when washed by rainwater.

3. High weather resistance, superior acid resistance, alkali resistance, long service life.

4. Strong adhesion, thick paint film, can effectively cover small cracks in the wall.

5. Water-based systems, health and environmental protection, construction safety.

6. Compared to traditional stone materials, the cost is low, and the construction is not limited by the geometry of the building.

Product Application

Applicable to various building exterior walls (new construction and renovation), various building interior walls, such as high-end residences, office buildings, hotels, villas, various decorative panels, exterior wall insulation materials decoration, special shaped decorative columns, etc.

Instructions

Theoretical paint consumption

2-3m²/kg. The actual amount of paint consumption will vary depending on the roughness and surface effect of the construction surface.

Dilution

If it needs to be stirred during use, it is recommended to stir it upside down, and it is not recommended to stir or add water to dilute.

Surface condition

The surface of the precoated substrate must be firm, dry, clean, smooth and free of loose matter.

Ensure that the surface humidity of the precoated substrate is less than 10% and the pH is less than 10.

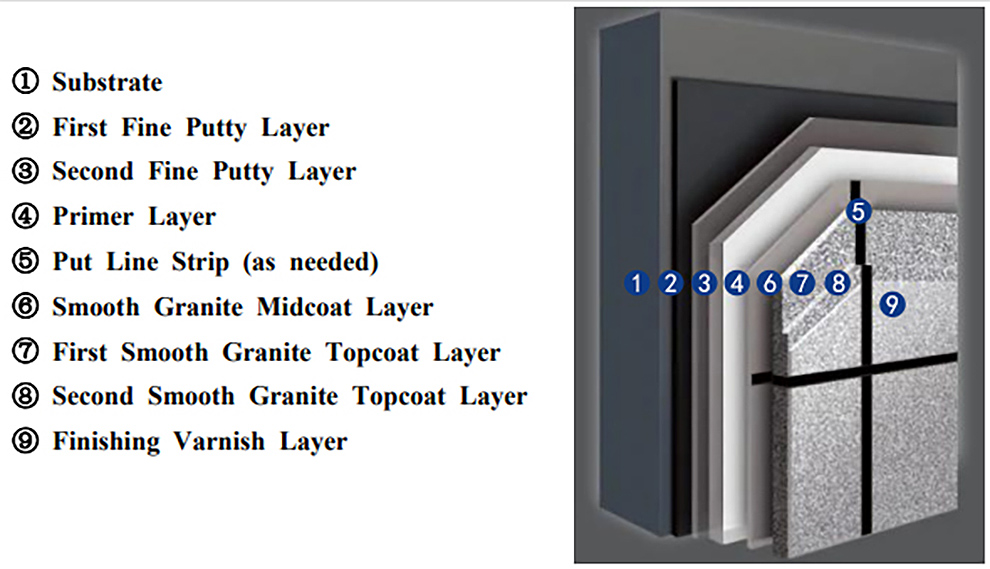

Coating system and coating times

♦ Base treatment: check whether the wall surface is smooth, dry, free of dirt, hollowing, cracking, etc., and repair it with cement slurry or exterior wall putty if necessary.

♦ Construction primer: apply a layer of moisture-proof and alkali-resistant sealing primer on the base layer by spraying or rolling to enhance waterproof, moisture-proof effect and bonding strength.

♦ Separation line processing: If a grid pattern is required, use a ruler or a marking line to make a straight line mark, and cover and paste it with washi tape. Note that the horizontal line is pasted first and the vertical line is pasted later, and iron nails can be nailed to the joints.

♦ Spray real stone paint: Stir the real stone paint evenly, install it in a special spray gun, and spray it from top to bottom and from left to right. The thickness of spraying is about 2-3mm, and the number of times is two times. Pay attention to adjusting the nozzle diameter and distance to achieve the ideal spot size and convex and concave feel.

♦ Remove the mesh tape: Before the real stone paint is dry, carefully tear off the tape along the seam, and be careful not to affect the cut corners of the coating film. The removal sequence is to remove the horizontal lines first and then the vertical lines.

♦ Water-in-sand primer: Apply water-in-sand primer on the dried primer surface to make it cover evenly and wait for drying.

♦ Respray and repair: Check the construction surface in time, and repair parts such as through-bottom, missing spray, uneven color, and unclear lines until they meet the requirements.

♦ Grinding: After the real stone paint is completely dry and hardened, use 400-600 mesh abrasive cloth to polish the sharp-angled stone particles on the surface to increase the beauty of the crushed stone and reduce the damage of the sharp stone particles to the topcoat.

♦ Construction finish paint: Use an air pump to blow off the floating ash on the surface of the real stone paint, and then spray or roll the finish paint all over to improve the waterproof and stain resistance of the real stone paint. The finished paint can be sprayed twice with an interval of 2 hours.

♦ Demolition protection: After the construction of the topcoat is completed, check and accept all construction parts, and remove the protective facilities on doors, windows and other parts after confirming that they are correct.

Maintenance time

7 days/25°C, low temperature (not lower than 5°C) should be extended appropriately to obtain the ideal paint film effect.

Powdered surface

1. Remove the powdered coating from the surface as much as possible, and level it again with putty.

2. After the putty is dry, smooth with fine sandpaper and remove powder.

Moldy surface

1. Shovel with a spatula and sand with sandpaper to remove mildew.

2. Brush 1 time with appropriate mold washing water, and wash it with clean water in time, and let it dry completely.

Packaging specification

20KG

Storage method

Store in a cool and dry warehouse at 0°C-35°C, avoid rain and sun exposure, and strictly prevent frost. Avoid stacking too high.

Points to Attention

Construction and use suggestions

1. Carefully read the instructions for using this product before construction.

2. It is recommended to try it in a small area first, and if you have any questions, please consult on time before using it.

3. Avoid storage at low temperatures or exposure to sunlight.

4. Use according to product technical instructions.

Executive standard

The product complies with GB/T9755-2014 "Synthetic Resin Emulsion Exterior Wall Coatings.

Product construction steps

Product Display

Substrate Treatment

1. New wall: Thoroughly remove surface dust, oil stains, loose plaster, etc., and repair any holes to ensure that the wall surface is clean, dry and even.

2. Re-painting wall: Thoroughly remove the original paint film and putty layer, clean surface dust, and level, polish, clean and thoroughly dry the surface, so as to avoid problems left over from the old wall (odor, mildew, etc.) affecting the application effect.

*Before coating, the substrate should be checked; coating can only start after the substrate has passed acceptance inspection.

Precautions

1. Please work in a well-ventilated environment, and wear a protective mask when polishing the wall.

2. During construction, please configure necessary protective and labor protection products according to local operating regulations, such as protective glasses, gloves and professional spraying clothing.

3. If it gets into eyes accidentally, please rinse well with plenty of water and seek medical treatment immediately.

4. Do not pour the remaining paint liquid into the sewer to avoid clogging. When disposing of paint waste, please comply with local environmental protection standards.

5. This product must be sealed and stored in a cool and dry place at 0-40°C. Please refer to the label for details on production date, batch number and shelf life.